Why Splashback Thickness Matters

Traditionally, wall protection near heat and water has always favored materials that balance strength with practicality. Glass splashbacks follow the same rulebook.

Thickness impacts:

Heat resistance behind cooktops

Structural stability during installation

Edge finishing and cut-out precision

Cost control and lead times

Get this wrong, and you introduce unnecessary risk into an otherwise straightforward upgrade.

The Industry Standard: 6mm Glass Splashbacks

6mm toughened glass is the market benchmark—and for good reason.

From an operational standpoint, it delivers:

Proven heat resistance (when correctly installed)

Safe handling and installation

Clean edge polishing

Consistent visual clarity and color accuracy

Suppliers like DIY Splashbacks default to 6mm because it aligns with decades of manufacturing data and installation outcomes. It’s the thickness that works—repeatedly.

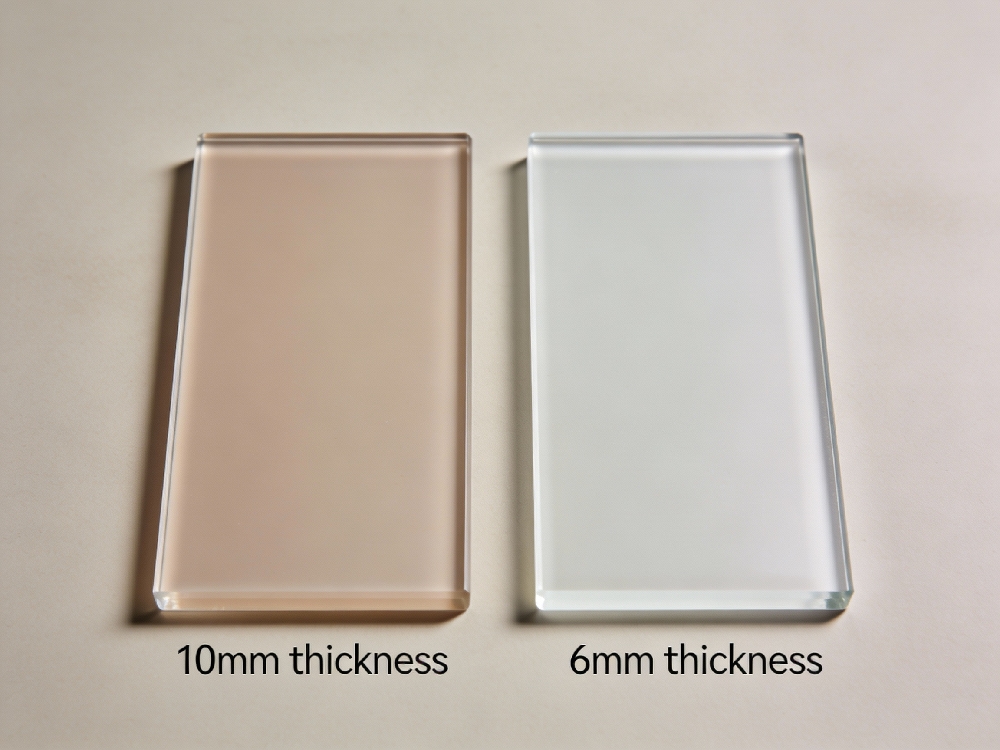

When Would You Use Thicker Glass (8mm or 10mm)?

Thicker splashbacks exist, but they’re context-specific, not the norm.

Consider thicker glass if:

The splashback is oversized or freestanding

It’s used as a feature panel, not just wall protection

The design brief prioritizes visual weight over efficiency

That said, thicker glass increases:

Cost

Installation complexity

Weight load on walls

From a traditional value perspective, thicker isn’t automatically better—it’s just heavier.

Is Thinner Than 6mm Ever Acceptable?

In short: no for kitchens.

Anything below 6mm introduces unnecessary fragility and compromises safety near heat sources. Historically, cutting corners on material thickness always costs more long term. Modern standards simply formalize that lesson.

Thickness and Heat: What You Need to Know

Glass splashbacks must be toughened regardless of thickness. However, 6mm toughened glass has the best track record when paired with proper clearances from gas or electric hobs.

Reputable suppliers—such as DIY Splashbacks—design thickness, cut-outs, and heat zones as a single system, not isolated decisions. That’s where risk mitigation happens.

Does Thickness Affect Color and Finish?

Yes—but subtly.

Thicker glass can deepen color tones

6mm glass delivers the most predictable color outcome

Digital printing and painted finishes are optimized for 6mm panels

From a brand and consistency standpoint, 6mm ensures what you see in samples is what you get on the wall.

Final Takeaway: Stick With What Works

If you’re making a decision based on:

Performance

Safety

Cost efficiency

Proven results

Then 6mm toughened glass remains the correct call for most residential splashbacks.

It’s the thickness the industry was built on—and the one modern suppliers like DIY Splashbacks continue to stand behind because it delivers predictable outcomes at scale.