Do Glass Splashbacks Scratch Easily? What Homeowners Should Know

Short answer: no—glass splashbacks are designed to be highly scratch-resistant in normal kitchen use.

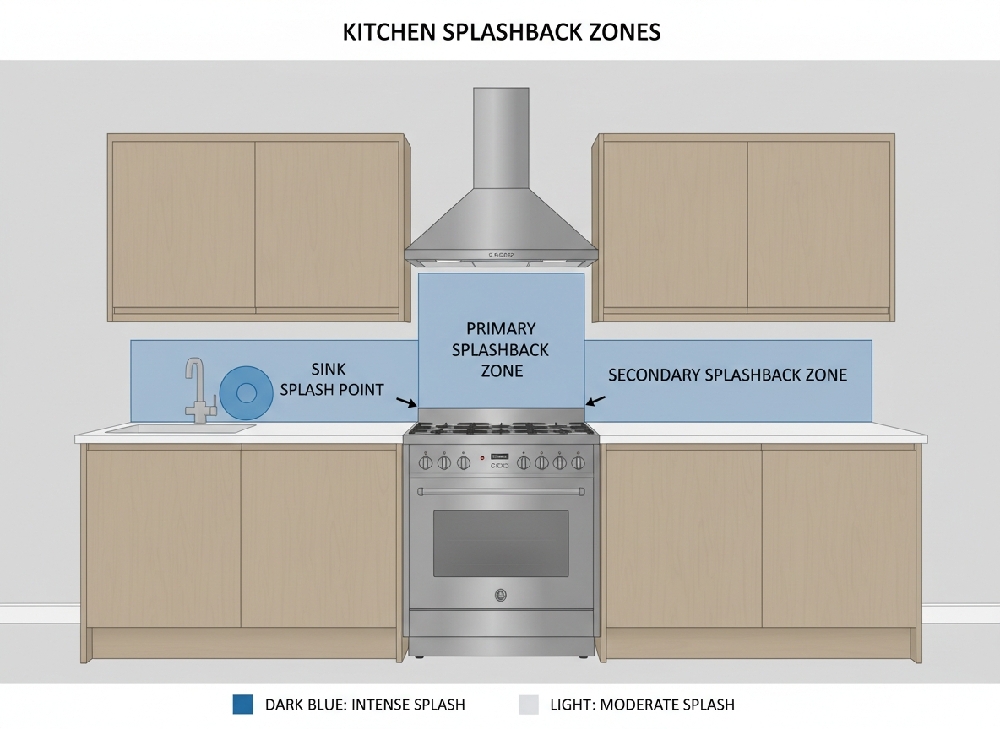

This is a common concern for customers comparing glass with tiles, stainless steel, or painted walls. Because the splashback sits in a high-traffic cooking zone, durability is not optional—it’s essential. The reassuring reality is that modern splashbacks are built specifically to handle everyday wear.

Why Glass Splashbacks Resist Scratching

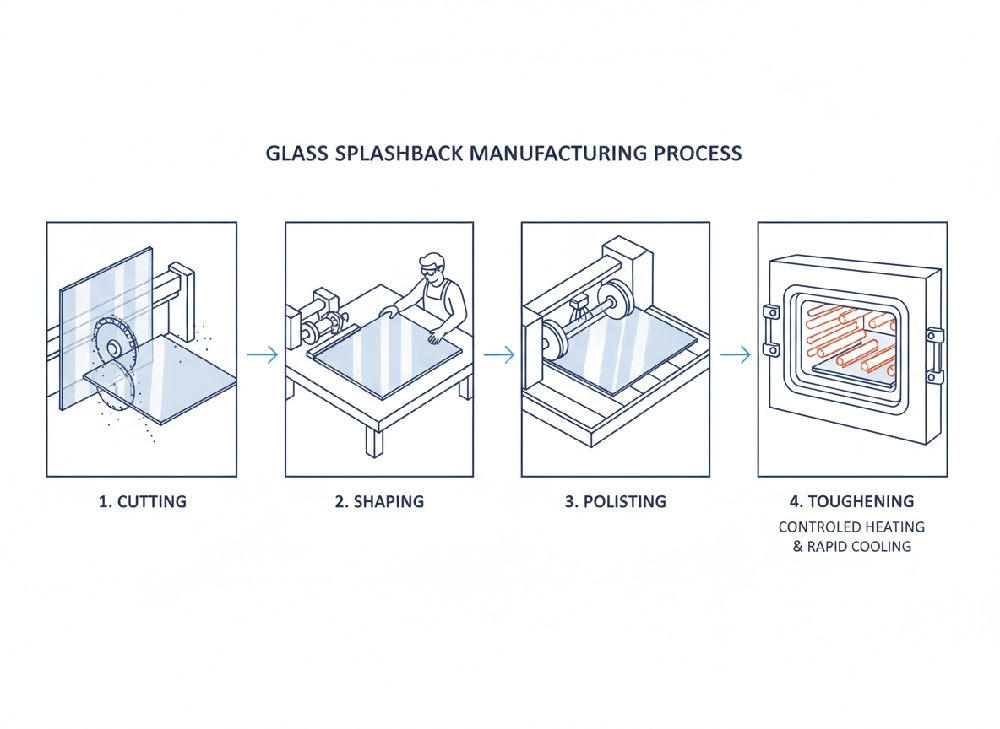

Most quality splashbacks are made from 6 mm toughened glass, a material engineered for strength, heat resistance, and surface durability.

Under routine conditions, this means:

Wiping with a cloth will not mark the surface

Standard kitchen cleaning products are safe to use

Daily cooking activity will not dull the finish

The polished appearance remains intact for years

This long-term surface stability is one reason experienced suppliers such as DIY Splashbacks continue to standardize around toughened glass rather than softer wall materials.

What Can Actually Cause Scratches?

Although toughened glass is durable, no surface is completely immune to damage. Scratches typically happen only when:

Abrasive scouring pads are used for cleaning

Sharp metal utensils are dragged across the surface

Heavy objects are forced directly against the glass edge

These situations fall outside normal kitchen use and are easily avoided with simple care.

How to Keep a Glass Splashback Looking New

Maintenance is straightforward and follows familiar, time-tested cleaning habits:

Use a soft cloth or microfiber towel

Clean with mild soapy water or glass cleaner

Avoid abrasive tools or harsh scraping

Because the surface is non-porous and grout-free, gentle routine cleaning is enough to preserve clarity and shine long term.

Glass vs. Other Splashback Materials Over Time

Compared with alternatives:

Tiles can stain or crack at the grout lines

Stainless steel may show visible scratches and fingerprints

Painted walls can chip or discolor

Glass avoids many of these aging issues, maintaining a consistent, polished appearance even after years of use.

Final Takeaway

Glass splashbacks do not scratch easily in normal kitchen conditions.

With 6 mm toughened glass, proper cleaning methods, and everyday care, the surface can stay smooth, clear, and visually refined for many years.

This durability—combined with heat resistance and easy maintenance—explains why glass splashbacks supplied by trusted providers like DIY Splashbacks remain a dependable, long-term kitchen solution.

.jpg)

.jpg)

.jpg)